Uncovering the Unseen with Penetrant Testing

Penetrant testing (PT) is a highly effective, non-destructive method for identifying surface-breaking defects in a wide range of materials. By applying a liquid dye to the surface, we can reveal cracks, porosity, and other imperfections that are invisible to the naked eye. Our expert technicians ensure accurate and reliable results, providing you with the confidence that your components meet the highest standards of safety and quality.

Visible Penetrant

Visible penetrant testing utilizes a red dye to highlight surface defects, which can be easily seen under normal lighting conditions. It's a cost-effective method for detecting surface flaws in a variety of materials.

Water Washable

Water-washable penetrants are applied and then removed using water, leaving only visible or fluorescent indications of defects. This method is quick and efficient for clean, non-porous surfaces.

Solvent Removable

In this technique, the penetrant is removed using a solvent, making it a versatile method for detecting surface defects in both simple and complex geometries without affecting the part’s surface integrity.

Post Emulsifiable

Post-emulsifiable penetrants use a special emulsifier to remove excess penetrant after application. This technique is ideal for materials with rough or porous surfaces, ensuring accurate detection of surface defects.

Hydrophilic Post-Emulsifiable

Hydrophilic post-emulsifiable uses a water-based emulsifier to remove excess penetrant after its applied. This method is particularly effective for detecting surface defects on materials with rough or porous surfaces.

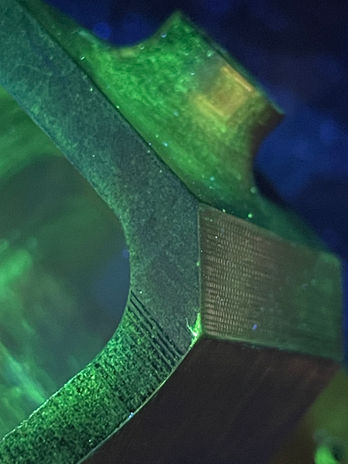

Fluorescent Penetrant

Fluorescent penetrant testing uses a fluorescent dye that glows under ultraviolet light, making surface defects highly visible. This method is ideal for detecting very fine cracks and other small surface imperfections.